|

With

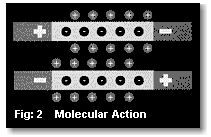

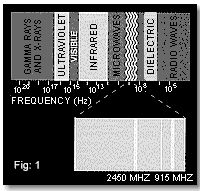

microwaves, no heat is applied per se. Instead a form of radio waves

(not nuclear nor ionizing radiation (see Fig.1) pass through the

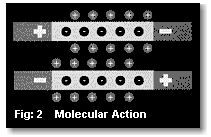

material. The molecules in the material then act like miniature

magnets attempting to align themselves with the electrical field.

Under the influence of this high frequency alternating electrical

field, the particles oscillate about their axes creating intermolecular

friction which manifests itself as heat (see Fig. 2) With

microwaves, no heat is applied per se. Instead a form of radio waves

(not nuclear nor ionizing radiation (see Fig.1) pass through the

material. The molecules in the material then act like miniature

magnets attempting to align themselves with the electrical field.

Under the influence of this high frequency alternating electrical

field, the particles oscillate about their axes creating intermolecular

friction which manifests itself as heat (see Fig. 2)

What

are the advantages...

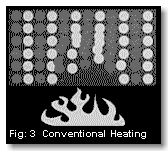

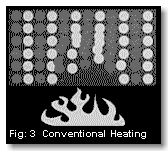

In conventional heating the heat source causes the

molecules to react from the surface toward the center (see Fig.

3) so that successive layers of molecules heat in turn. The product

surfaces may be in danger of over heating by the time heat penetrates

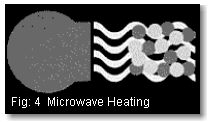

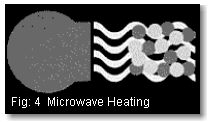

the material. Microwaves, however, produce a volume heating effect.

All molecules are set in action at the same time (see Fig. 4). It

also evens temperature gradients and offers other important benefits.

Examples... Examples...

A producer of fat-free potato chips was awarded a

patent using a microwave system designed by Microdry making it possible

to produce a potato chip with the characteristics of a fried chip

without the use of oil.

The pre-drying

stage of ceramic filters used in smelting processes can be cut from

hours to minutes due to the ability of the microwave energy to penetrate

the material and force the moisture to the surface greatly reducing

time and energy consumption since the ovens operate at nearly 80%

efficiency.

A manufacturer

of building supplies replaced costly, less efficient equipment with

Microdrys' microwave equipment giving them a clear competitive edge

over their competitors while also allowing them to use less costly

raw materials and reduce the cutting of forests as well.

How

does an industrial microwave system differ from a home microwave

oven...

The home/restaurant batch-type ovens available to

date employ a relatively low power source as compared to the industrial

power source. This makes producing products beyond pilot scale levels

very labor intensive. In addition, the typical home oven is considerably

less efficient, up to 25% less, in converting electrical energy

into microwave energy. By comparison the industrial oven can be

designed as either a batch or as a continuous system with much higher

power and greatly increased throughputs, reducing the amount of

handling required. In addition, a forced air system can also be

employed, which greatly improves moisture removal in drying applications.

- The system

employs a high energy power source with long life.

- The system

has a unique internal protection feature (patented) that traps

stray microwaves, thus making the system completely safe to

operate. A new exclusive type of forced-air system used in conjunction

with microwave energy (patented) accelerates the removal of

moisture quickly and efficiently.

- A straight-through

conveyor assures uniform exposure to the microwaves.

- Because

of its high processing capacity, unit costs are much lower than

with the batch proces

Return

to the Articles Section

|

When

microwave heating can be used - and is used properly - almost certainly

you will process more product in less time at lower cost. Throughout

history there has been one way to heat materials: apply heat to its

surface. About thirty years ago, industrial engineers began developing

microwave heating techniques that avoid some limitations of conventional

heating.

When

microwave heating can be used - and is used properly - almost certainly

you will process more product in less time at lower cost. Throughout

history there has been one way to heat materials: apply heat to its

surface. About thirty years ago, industrial engineers began developing

microwave heating techniques that avoid some limitations of conventional

heating.

With

microwaves, no heat is applied per se. Instead a form of radio waves

(not nuclear nor ionizing radiation (see Fig.1) pass through the

material. The molecules in the material then act like miniature

magnets attempting to align themselves with the electrical field.

Under the influence of this high frequency alternating electrical

field, the particles oscillate about their axes creating intermolecular

friction which manifests itself as heat (see Fig. 2)

With

microwaves, no heat is applied per se. Instead a form of radio waves

(not nuclear nor ionizing radiation (see Fig.1) pass through the

material. The molecules in the material then act like miniature

magnets attempting to align themselves with the electrical field.

Under the influence of this high frequency alternating electrical

field, the particles oscillate about their axes creating intermolecular

friction which manifests itself as heat (see Fig. 2)

Examples...

Examples...